Milling

- VMC (Vertical Machining Center):

- Precision: Capable of maintaining tolerances as tight as ±5 microns for complex parts.

- Technology: Advanced milling technology for high-precision, intricate components.

- Maintenance: Includes regular calibration, tool monitoring, and spindle checks for consistent accuracy.

- Safety: Features enclosed work areas and automated safety checks to protect operators.

- ISO 9001 Compliance: VMC operations are fully compliant with ISO standards, ensuring top-tier quality.

Milling is a versatile machining process for creating detailed shapes by removing material with rotary cutters. It is crucial for producing components with complex geometries.

- Milling Machine:

- Precision: Maintains dimensional accuracy with tolerances up to ±10 microns.

- Versatility: Capable of handling various milling tasks, from simple cuts to complex contours.

- Maintenance: Regular inspection of cutters, spindle, and coolant systems is essential for reliable operation.

- Safety: Machine guarding, emergency stops, and coolant containment ensure operator protection.

- ISO 9001 Compliance: Milling operations are standardized to meet ISO quality control requirements.

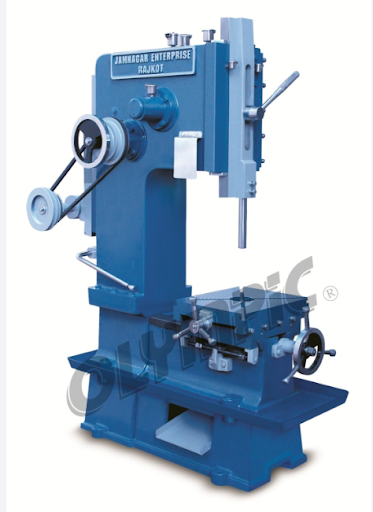

- Slotting Machines:

- Precision: Ensures accurate slotting and keyway production with tight tolerances.

- Specialization: Designed for creating precise slots and grooves in components.

- Maintenance: Periodic alignment checks and lubrication of moving parts maintain operational accuracy.

- Safety: Equipped with interlock systems and operator shields for safe use.

- ISO 9001 Compliance: Slotting processes adhere to ISO standards, ensuring high-quality output.